Great Info About Can I Use 220v Wire For 12V

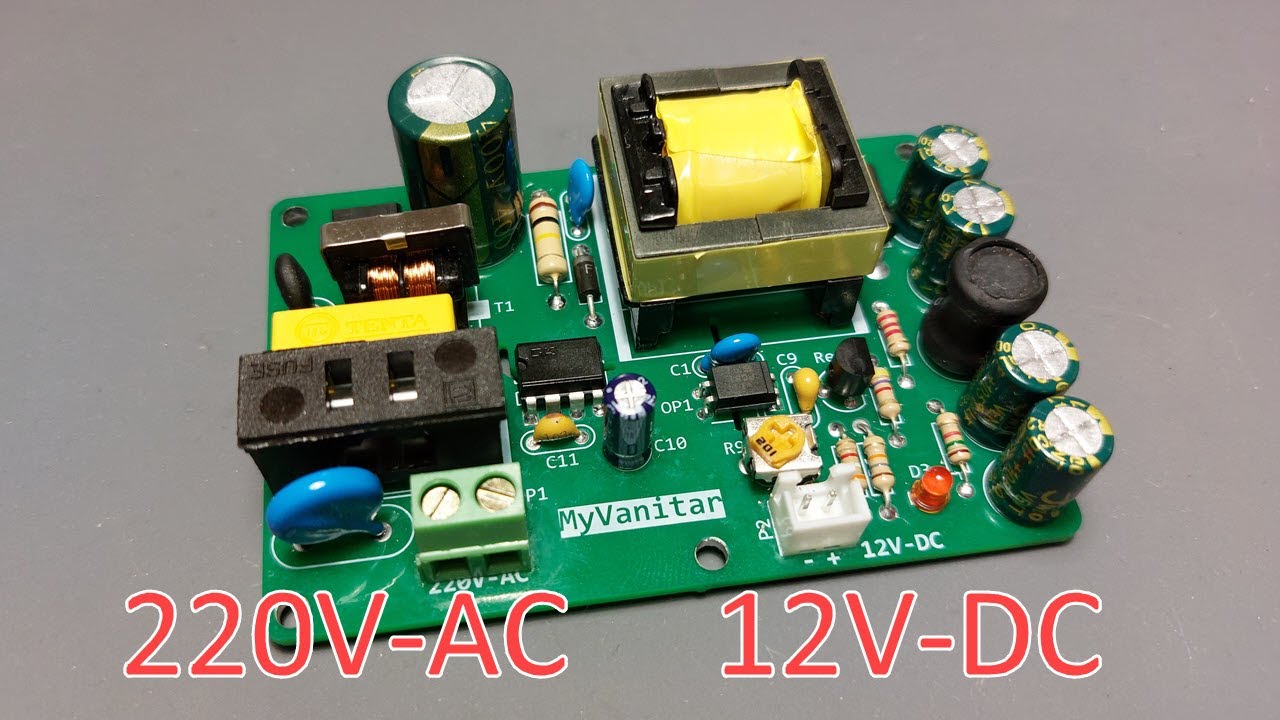

220VAC To 12VDC, 18W Switching Power Supply YouTube

Understanding Wire Gauges and Voltage

1. What's the Deal with Wire and Voltage?

So, you're staring at a spool of 220V wire and thinking, "Hey, could I use this for my 12V project?" Maybe you're rewiring a car stereo or setting up some snazzy LED lighting. Its a valid question! Let's break down the electrifying facts about wire, voltage, and why simply swapping them isn't always a bright idea. It's like trying to fit a square peg in a round hole — sometimes it works with enough hammering, but usually, there's a better way that avoids property damage!

The truth is, you can often use 220V-rated wire for a 12V application, but it's not primarily about the voltage rating itself. The main concern is the wire gauge, which dictates how much current the wire can safely handle. Think of the wire like a pipe — the wider the pipe, the more water (or electricity) it can carry. A thicker wire, designed for higher voltage applications, will definitely be able to handle the lower voltage. But there are a couple of important "buts" we need to consider.

Wire insulation also plays a role. 220V wire typically has thicker insulation to withstand higher voltages. While this isn't necessarily a problem for a 12V system, it can make the wire bulkier and harder to work with, especially in tight spaces. Imagine trying to thread a garden hose through a straw — frustrating, right? It's the same principle. So, while technically possible, it may not be practical.

Ultimately, safety and efficiency are paramount. You wouldn't want a wire getting so hot it melts the insulation and starts a fire! So, understanding the current requirements of your 12V circuit is crucial. Check the amperage (amps) your device draws. Then, consult a wire gauge chart to determine the appropriate wire size. Using a wire that's too thin can lead to voltage drop, overheating, and even fire hazards. Think of it as feeding a starving bear a single pea — it's just not enough, and it can lead to trouble!

Current and Gauge

2. Why Amperage Matters More Than Voltage

Let's dive a little deeper. Remember, the voltage rating of a wire indicates the maximum voltage it can safely insulate against. It's like the maximum weight a bridge can handle. Just because a bridge can hold 10 tons doesn't mean you have to drive a 10-ton truck over it. You can still use your bicycle! Similarly, a 220V wire is built to withstand 220V, but it's perfectly fine to use it for a lower voltage.

However, the current (measured in amps) is what truly heats up the wire. Think of it as the number of cars driving across that bridge simultaneously. Too many cars, and the bridge becomes stressed. Too much current, and the wire overheats. This is where wire gauge comes in. The gauge (AWG — American Wire Gauge) indicates the wire's thickness. A lower gauge number means a thicker wire, and a thicker wire can handle more current. Its all about capacity!

Imagine trying to force a river through a garden hose. The hose would likely burst! The same happens with electricity. If you try to push too much current through a wire that's too thin, it will overheat and potentially melt, causing a fire hazard. Thats why matching the wire gauge to the amperage requirements of your circuit is crucial. There are readily available wire gauge charts online that you can use to find the right gauge for your specific application. Don't guess; check!

So, to reiterate, using a 220V wire for a 12V application is generally safe if the wire gauge is appropriate for the current draw of the 12V circuit. Don't focus solely on the voltage rating. Focus on whether the wire can handle the amps without overheating. Its like focusing on the paint job of a car when the engine is about to blow — youre missing the critical part!

Practical Considerations and Caveats

3. When to Think Twice Before You Wire

While technically feasible, there are some practical considerations before you grab that 220V wire for your low-voltage project. One is workability. 220V wire often has thicker insulation, making it stiffer and harder to bend and manipulate, especially in tight spaces. Trying to squeeze it into a small connector or around a sharp corner can be a real pain. Its like trying to fold a fitted sheet neatly — possible, but frustrating!

Another thing to consider is cost. 220V wire might be more expensive than appropriately sized 12V wire. Why pay more for something that's overkill? It's like buying a monster truck to drive to the grocery store — it gets the job done, but it's not the most efficient choice. You might as well be throwing money at the problem!

Furthermore, using oversized wire can sometimes lead to connection issues. Smaller connectors might not be able to accommodate the thicker wire properly, leading to loose connections and potential problems down the line. Its like trying to wear shoes that are two sizes too big — you might be able to shuffle around, but it's not ideal and you're likely to trip!

Finally, and this is important: Always, always check local electrical codes and regulations. Some jurisdictions may have specific requirements regarding wire types and installations, regardless of voltage. It's better to be safe than sorry (and potentially fined!). It's like ignoring the speed limit — you might get away with it, but the consequences can be costly.

Alternatives and Best Practices

4. Choosing the Right Wire for the Job

So, what's the best approach? Ideally, use wire that's specifically designed and sized for your 12V application. Automotive wire (GPT, GXL, SXL) is a good choice for car-related projects, as it's designed to withstand the harsh conditions of a vehicle's engine compartment. Speaker wire is another common option for low-voltage audio applications.

When selecting wire, always refer to a wire gauge chart to determine the appropriate size based on the current draw of your circuit and the length of the wire run. Voltage drop can become a significant issue over longer distances, requiring a thicker wire to maintain adequate voltage at the load. It's like trying to water a garden at the end of a long hose — the pressure drops off, so you need a bigger hose for optimal results.

Also, pay attention to the wire's insulation type. PVC insulation is common and suitable for general-purpose applications. However, for high-temperature environments, consider using wire with Teflon or other high-temperature insulation. Its all about choosing the right tool for the job!

Finally, when making connections, use proper crimping tools and connectors to ensure secure and reliable connections. Avoid using wire nuts for low-voltage DC circuits, as they can loosen over time and cause problems. Properly crimped connections provide a gas-tight seal that prevents corrosion and ensures good electrical conductivity. Think of it as building a house — a strong foundation is essential for long-term stability.

How To Wire 12v Batteries In Series

FAQ

5. Frequently Asked Questions About Wire and Voltage

Here are some common questions that come up when discussing wire and voltage:

6. Q

A: Nope! The voltage rating doesn't magically boost the performance of your 12V device. It simply means the wire is insulated to handle higher voltages. The current-carrying capacity is what matters for performance and safety.

7. Q

A: Bad things! The wire will overheat, potentially melting the insulation and creating a fire hazard. It can also cause voltage drop, resulting in poor performance of your device. Think dim lights, weak sound, or a motor that won't start.

8. Q

A: While technically you could, it's not recommended. Extension cord wire is typically stranded copper, which is good, but the insulation isn't designed for the harsh environment of a car. Automotive wire is more resistant to heat, chemicals, and abrasion. It's a worthwhile investment for safety and reliability.