Favorite Info About How To Protect MOSFET From Back EMF

Mosfet Free Wheeling (back EMF) Diode For Latching Relay Electrical

Understanding Back EMF and MOSFETs

1. What's Back EMF Anyway?

Alright, lets picture this: youve got a MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor), a real workhorse in the electronics world, happily switching a load, like a motor or an inductor. Everything seems smooth, right? Well, hold on a second. When you suddenly switch that load off, the energy stored in the inductor doesn't just vanish into thin air. Nope, it retaliates in the form of back electromotive force (EMF), also known as inductive kickback. Think of it like letting the air out of a balloon suddenly, there's a lot of pent-up energy looking for a way out!

Back EMF is basically a voltage spike that can be significantly higher than the voltage you were initially using to power the load. It's like the load is shouting, "Hey, I don't want to stop! Im going to create a voltage to keep the current flowing!". This sudden surge of voltage can be incredibly damaging to your delicate MOSFET, potentially leading to its untimely demise. It's a bit like trying to run a marathon after sitting on the couch for a year something's gonna break.

So, why is this back EMF created? Well, inductors resist changes in current. When you try to rapidly stop the current flow, the inductor generates a voltage to counteract that change. This voltage, our dear back EMF, tries to maintain the current that was previously flowing. This is crucial to understanding because if your MOSFET cant handle that voltage it will be damaged. Knowing this alone is half the battle!

Now you might be thinking, "Okay, that sounds bad. But how bad can it really be?" Imagine trying to stop a speeding train with a bicycle brake. The outcome wouldn't be pretty, would it? Similarly, back EMF can easily exceed the MOSFET's voltage rating, causing it to fail catastrophically. We're talking burnt-out components, smoke, and potentially a whole lot of frustration. So, protecting your MOSFET from this back EMF is absolutely essential for ensuring the longevity and reliability of your electronic circuits.

TVS Diode Across Motor Leads Failing Short. How To Protect MOSFET From

The Usual Suspects

2. Diode to the Rescue!

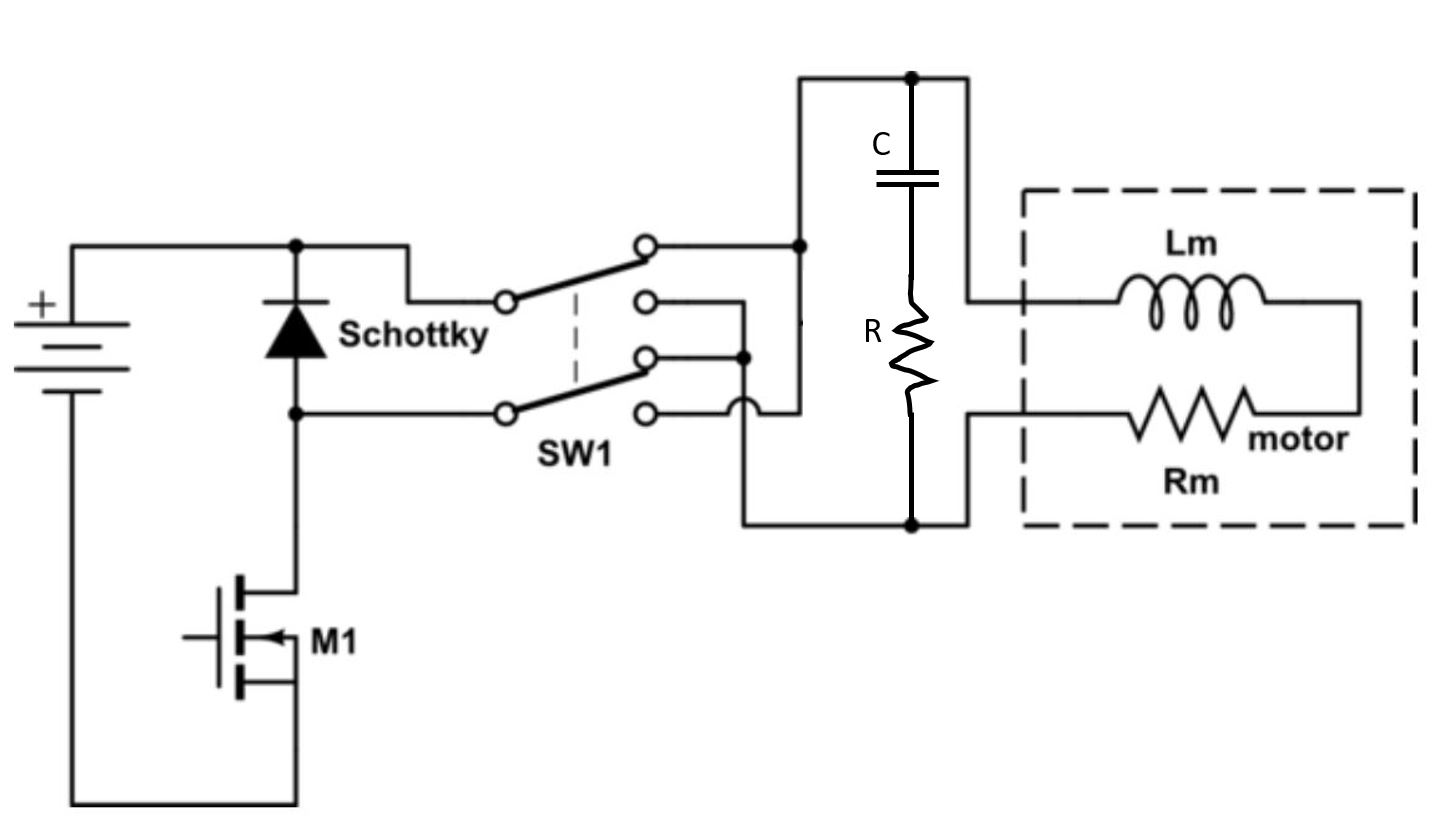

The most common, and often the simplest, method for protecting your MOSFET from back EMF is using a flyback diode. Also sometimes called a snubber diode or freewheeling diode. Picture a small, unassuming diode placed in parallel with the inductive load, but with a crucial detail: its connected in reverse bias. This means that under normal operating conditions, the diode doesn't do much; it just sits there quietly, minding its own business.

However, when the MOSFET switches off and back EMF appears, this diode springs into action. The back EMF voltage now forward biases the diode, allowing the current to flow through the diode instead of through the MOSFET. This provides a safe path for the energy stored in the inductor to dissipate, preventing the voltage from rising to dangerous levels. The diode effectively short-circuits the back EMF, shunting it away from your precious MOSFET.

Choosing the right diode is important. You'll want one that can handle the peak current and voltage generated by the back EMF. Also, its recovery time, how quickly it switches from off to on is important. A fast recovery diode ensures it switches on before damaging voltage appear at the MOSFET. Think of it as having a lightning-fast reflex in a crucial moment.

The beauty of the flyback diode is its simplicity and effectiveness. Its a cost-effective way to provide robust protection against back EMF, making it a staple in countless electronic designs. It's the unsung hero, quietly safeguarding your MOSFET from potential destruction.

3. RC Snubbers

Sometimes, a simple flyback diode isnt quite enough, especially when dealing with very fast switching speeds or particularly "noisy" inductors. In these cases, you might need to bring in the big guns: the RC snubber circuit. An RC snubber consists of a resistor and a capacitor connected in series, placed in parallel with the inductive load. The purpose of the RC snubber is to dampen the voltage ringing caused by the back EMF.

Voltage ringing happens because the inductance of the load and any stray capacitance in the circuit (like the MOSFET's own capacitance) can form a resonant circuit. When the MOSFET switches off, this resonant circuit starts oscillating, creating a series of voltage spikes that can stress the MOSFET. The RC snubber acts like a shock absorber, dissipating the energy of these oscillations and preventing them from reaching damaging levels.

The resistor in the snubber helps to dampen the oscillations, while the capacitor absorbs the initial voltage spike. Choosing the right values for the resistor and capacitor is crucial for optimal performance. There are equations and simulations that can help, but often some trial and error is needed to tune the snubber to your specific circuit.

While RC snubbers are more complex than simple flyback diodes, they offer superior protection against voltage ringing and can significantly improve the reliability of your MOSFET. They are particularly useful in applications where high switching speeds and low electromagnetic interference (EMI) are required. Theyre like the fine-tuning adjustment to a perfectly set engine.

Motor Back Emf Protection Circuit At Jason Lindstrom Blog

Practical Considerations

4. Diode Selection Criteria

Okay, so you're convinced that a flyback diode is the way to go (and in many cases, it is!). But which diode should you choose? Not all diodes are created equal. Key parameters to consider include the diodes peak inverse voltage (PIV), forward current rating, and reverse recovery time.

The PIV should be significantly higher than the maximum voltage you expect to see during back EMF. A good rule of thumb is to choose a diode with a PIV at least twice the supply voltage. This provides a safety margin to account for any unexpected voltage spikes. The forward current rating should also be higher than the maximum current flowing through the inductor during normal operation. You don't want the diode to burn out when it's trying to save the day!

Reverse recovery time is how quickly the diode can stop conducting after it has been conducting. A diode with a fast reverse recovery time is essential for high-speed switching applications. A slow diode can actually make the problem worse by allowing a large current spike to flow through the MOSFET during the turn-off transition. Fast recovery diodes are readily available and are generally the best choice for MOSFET protection.

Dont skimp on the diode! Spending a few extra cents on a robust, high-quality diode can save you a whole lot of trouble down the road. Think of it as an insurance policy for your MOSFET. It's a relatively small investment that can prevent a potentially catastrophic failure.

5. Snubber Component Selection

If you've decided to go the RC snubber route, selecting the right resistor and capacitor values is crucial. Unfortunately, theres no one-size-fits-all formula, as the optimal values depend on the specific characteristics of your circuit, including the inductance of the load, the stray capacitance, and the switching frequency.

Generally, you'll want to start with a relatively small capacitor value and a resistor value that provides adequate damping. Too small of a resistor and you wont have enough damping. Too large, the snubber will consume too much power. Experimentation is often required. Simulation tools can be helpful for estimating the optimal values. These tools allow you to model your circuit and simulate the effects of different snubber component values.

When choosing the capacitor, be sure to select one that is rated for the expected voltage and current. Also, consider the capacitor's equivalent series resistance (ESR), which can affect the snubber's damping performance. For the resistor, choose a non-inductive resistor to avoid adding more inductance to the circuit. Power rating of the resistor is crucial, make sure it can handle the power during switching operation.

The RC snubber selection process can be a bit of an art, requiring careful analysis and experimentation. But with the right components, you can effectively tame the voltage ringing and protect your MOSFET from harm. Its just like finding the perfect wine to pair with a meal it takes a little effort, but the result is well worth it.

Layout Considerations

6. Minimizing Inductance

Even with the best protection components, poor circuit layout can still lead to problems with back EMF. The key is to minimize inductance in the current loop containing the MOSFET, the inductive load, and the protection device (diode or snubber). Inductance in this loop can exacerbate voltage ringing and reduce the effectiveness of the protection circuit.

Keep the leads of the components as short as possible, and place the flyback diode or snubber circuit as close as possible to the MOSFET and the inductive load. Avoid long, meandering traces, which can add significant inductance. Use ground planes to provide a low-impedance return path for the current. A good ground plane can significantly reduce noise and improve circuit performance.

Careful routing of traces is also important. Avoid creating large loops in the current path. If possible, use surface-mount components to minimize lead inductance. Surface-mount components have shorter leads than through-hole components, which reduces inductance and improves high-frequency performance.

Think of your circuit layout as a plumbing system. You want to ensure that the current has a clear, unobstructed path to flow through. Any kinks or bottlenecks in the system can lead to increased inductance and potential problems with back EMF. Proper layout is key to minimizing the impact of back EMF and protecting your MOSFET.

7. Grounding Strategy

A solid grounding strategy is crucial for minimizing noise and ensuring the effectiveness of your back EMF protection circuit. Use a star ground configuration, where all ground connections are tied to a single point. This helps to prevent ground loops, which can introduce noise and degrade circuit performance. This is like having all roads lead to Rome; this helps keep everything organized.

Use a dedicated ground plane for sensitive analog and digital circuits. This provides a low-impedance return path for the current and helps to shield the circuit from external noise sources. Separate the power and ground planes to prevent noise from the power supply from coupling into the sensitive circuits. Keep the ground plane continuous and avoid cutting it with traces or vias.

Use decoupling capacitors near each integrated circuit to provide a local source of charge. These capacitors help to filter out noise on the power supply lines and prevent voltage droop during switching transients. Choose capacitors with low equivalent series inductance (ESL) for optimal performance.

A well-designed grounding system is essential for ensuring the stability and reliability of your circuit. It helps to minimize noise, prevent ground loops, and improve the effectiveness of your back EMF protection circuit. Its the bedrock upon which your entire electronic system rests.

MicroCap Tutorials MOSFET Overvoltage Protection PMOS (Zener) YouTube

FAQ

8. Q

9. A

Without protection, back EMF can destroy your MOSFET. The voltage spike exceeds the MOSFET's voltage rating, leading to immediate failure. Think burnt components and a hefty repair bill. Consider it like driving a car without insurance!

10. Q

11. A

While a Zener diode can be used, it's not ideal. Standard Zener diodes often have slower response times than fast recovery diodes, potentially allowing a harmful voltage spike to reach the MOSFET before the Zener kicks in. If you do use one, make sure it's a fast-acting Zener diode and carefully consider its power dissipation rating.

12. Q

13. A

Yes. Back EMF is primarily a concern with inductive loads like motors, solenoids, and transformers. Resistive loads don't store significant energy and therefore don't generate significant back EMF when switched off. With inductive loads, it's not an option, its a necessity!

14. Q

15. A

For very high switching speeds, you may need a combination of techniques. A flyback diode provides basic protection, while an RC snubber dampens voltage ringing. Advanced techniques such as active clamping circuits can also be employed for even more precise control of the back EMF voltage.