Painstaking Lessons Of Info About Why Is Modbus Still Used

On Video What Is Modbus And How Does It Work? Electrical

Modbus

1. The Resilient Protocol

Ever stumble upon something seemingly ancient, like a rotary phone, and wonder, "Wait, people still use this?" Modbus, in the world of industrial communication, sometimes gets that same reaction. Born in the late '70s (disco era!), you'd think it would have faded into obscurity, replaced by something shinier and newer. Yet, it's stubbornly hanging on, connecting devices in factories, power plants, and even your local wastewater treatment facility. So, what's the deal? Why is Modbus still used?

The core reason lies in its simplicity and open nature. Unlike some fancy, proprietary protocols that require expensive licenses and specialized equipment, Modbus is remarkably straightforward. It's like the plain text of industrial communication: easy to understand, easy to implement. That makes it incredibly accessible, especially for smaller operations or those working with legacy systems. It's the workhorse that just keeps chugging along, reliable and dependable.

Think of it like this: Modbus is the trusty old pickup truck of the industrial world. Sure, you could get a sleek, self-driving electric vehicle, but the pickup is proven, affordable, and can handle just about anything you throw at it. It may not be the flashiest option, but it gets the job done without a lot of fuss. And sometimes, that's exactly what you need.

Furthermore, the widespread adoption of Modbus over the years has created a massive installed base. Replacing all those devices would be a monumental undertaking, both in terms of cost and disruption. So, for many businesses, sticking with Modbus is simply the most practical and cost-effective solution.

How To Convert Modbus RTU TCP Using Weintek's Builtin

Cost-Effectiveness

2. The Frugal Choice

Lets face it, in the current economy, cost is a major factor in any business decision. Modbus excels in this department. Because its a non-proprietary, open-source protocol, there are no licensing fees to worry about. Imagine the savings! It's like finding out that your favorite coffee shop suddenly made refills free—a delightful surprise that keeps you coming back.

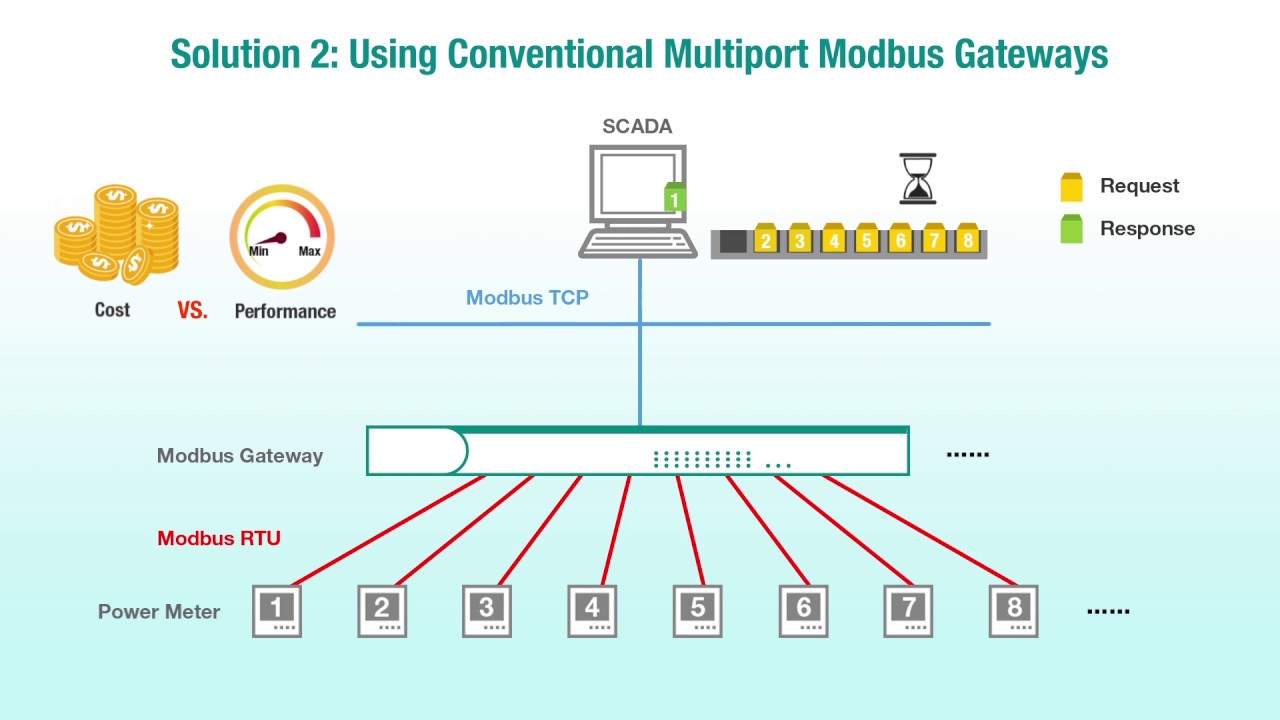

The hardware required to run Modbus is generally less expensive than that of more advanced protocols. This is particularly significant for larger networks where the cost of each device can quickly add up. Choosing Modbus can free up a significant portion of your budget for other essential investments. Think of it as choosing to drive a reliable sedan instead of a luxury sports car. Both get you where you need to go, but one leaves more money in your pocket.

Another aspect of cost-effectiveness is the ease of integration. Because Modbus is so widely supported, finding compatible devices and software is relatively simple. This reduces the amount of time and effort required to set up and maintain a Modbus network, further contributing to its overall affordability. You dont need to be a rocket scientist to get things running smoothly. It's almost like having a universal remote for your entire industrial process.

And lets not forget the long-term maintenance costs. Modbus, being a relatively simple protocol, is easier to troubleshoot and repair than more complex systems. This means that you can often handle maintenance tasks in-house, without the need for expensive external consultants. Think of it as being able to change your own oil instead of relying on a mechanic every time. It empowers you to take control of your operations and save money in the process.

Simplicity

3. Straightforward Communication

In a world of increasingly complex technology, Modbus stands out for its refreshing simplicity. It's like the dial-up internet of industrial protocols — not exactly cutting-edge, but undeniably easy to understand. This simplicity translates to easier implementation, troubleshooting, and maintenance. You dont need a PhD in computer science to get a Modbus network up and running.

The protocols straightforward structure makes it easier for developers to create and integrate new devices. There are plenty of resources and libraries available online, making it a breeze to find the tools you need. Its like having access to a well-stocked toolbox, complete with clear instructions for every project. Even if youre not an expert, you can still get the job done with confidence.

The reduced complexity of Modbus also means that it requires less processing power and memory than more sophisticated protocols. This makes it ideal for use in resource-constrained devices, such as sensors and small controllers. It's like choosing a lightweight backpack for a hiking trip — it allows you to carry more with less effort. This efficiency is particularly valuable in applications where battery life is critical.

Furthermore, the human readability of Modbus data contributes to its simplicity. The protocol uses simple numerical values to represent data, making it easy for operators to understand whats going on. This transparency can be invaluable for troubleshooting and optimization. Its like having a dashboard that clearly displays all the important information, allowing you to quickly identify any issues and take corrective action.

Lockerstart Blog

Versatility

4. Adaptable to Many Applications

Despite its age, Modbus has proven to be surprisingly versatile. It can be used in a wide range of industrial applications, from simple temperature monitoring to complex process control. This adaptability is one of the key reasons why its still around today. Its like that one tool in your garage that you can always count on to get the job done, no matter the task.

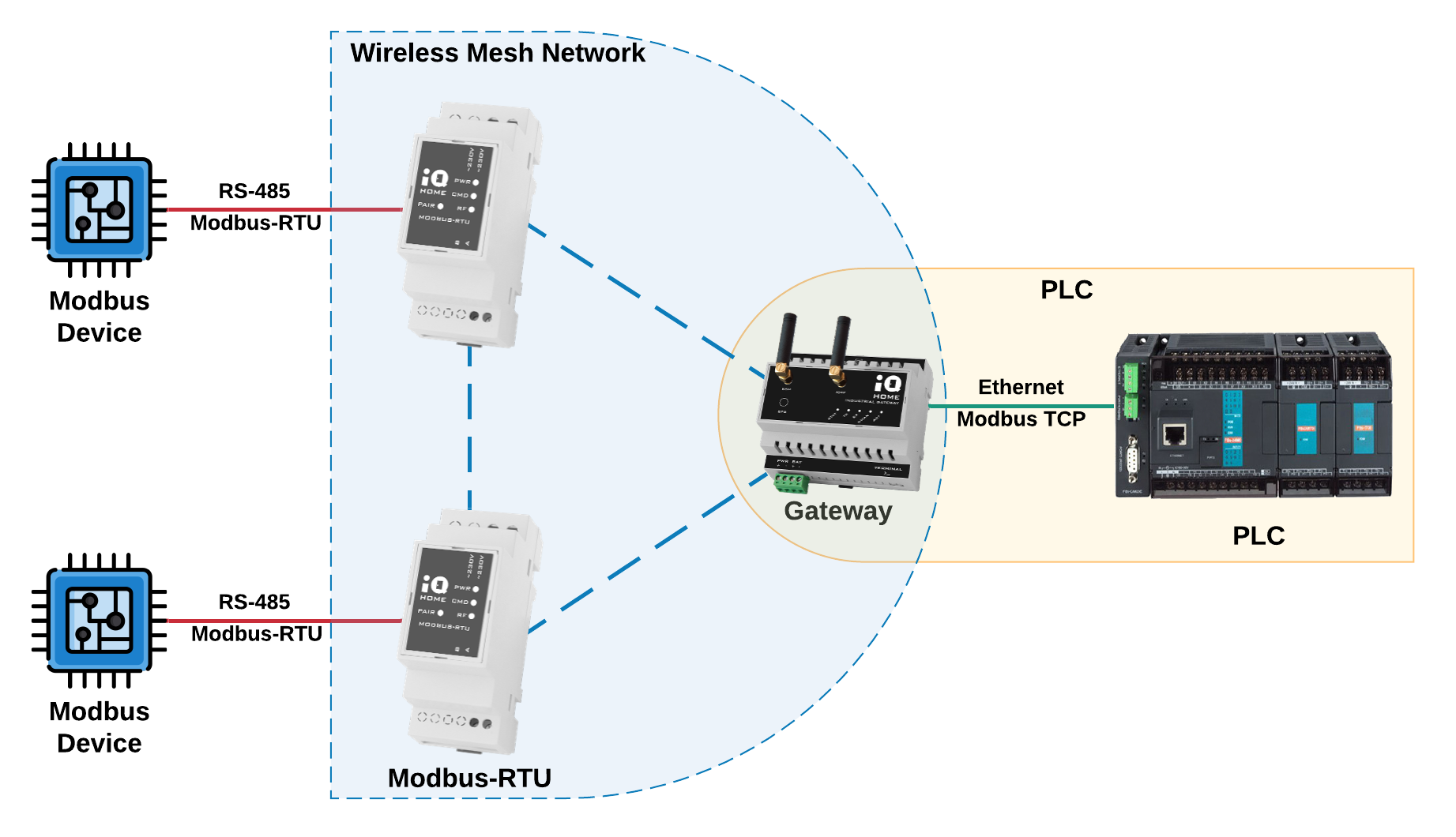

Modbus supports various communication media, including serial lines, Ethernet, and wireless networks. This flexibility allows it to be used in a variety of environments, from factories to remote monitoring stations. Its like having a universal adapter that can plug into any outlet, regardless of the voltage or plug type. This versatility makes it easy to integrate Modbus into existing infrastructure.

The protocols ability to connect to a wide range of devices, from different manufacturers, is another advantage. This interoperability is crucial in todays industrial environment, where systems often consist of components from multiple vendors. Its like having a common language that allows different people to communicate effectively, regardless of their native tongue. This compatibility reduces the risk of integration issues and simplifies system design.

And lets not forget the growing popularity of Modbus TCP/IP, which allows Modbus devices to communicate over Ethernet networks. This has extended the reach of Modbus to a wider range of applications, including cloud-based monitoring and control systems. Its like adding a GPS to your trusty old map, allowing you to navigate even more effectively. This adaptation to modern technology has ensured that Modbus remains relevant in the evolving industrial landscape.

Modbus RTU Vs TCP Industrial Automation

The "If It Ain't Broke..." Philosophy

5. The Legacy Factor

Sometimes, the best reason to stick with something is simply because it works. Modbus has been around for decades, and in that time, it has proven itself to be a reliable and effective communication protocol. Many industrial facilities have invested heavily in Modbus-based systems, and there's simply no compelling reason to replace them. Its like that favorite pair of jeans that youve had for years — comfortable, reliable, and always a good choice.

Replacing an entire industrial control system is a major undertaking, involving significant costs, downtime, and risk. Unless there's a clear and compelling benefit to switching to a newer protocol, many businesses prefer to stick with what they know. Its like deciding whether to renovate your entire house or simply make a few minor repairs. The latter is often the more practical and cost-effective option.

The availability of skilled technicians who are familiar with Modbus is another important factor. Many experienced engineers and technicians have spent their careers working with Modbus systems, and they have the knowledge and expertise to keep them running smoothly. Its like having a team of mechanics who know every nut and bolt of your car. Their expertise is invaluable for troubleshooting and maintenance.

And lets be honest, sometimes the fear of the unknown is a powerful motivator. Switching to a new protocol can introduce unexpected challenges and risks. Sticking with Modbus, on the other hand, is a known quantity. Its like choosing to stay on the familiar road instead of venturing into uncharted territory. Sometimes, the safest bet is simply to stick with what you know.

How Modbus Is Used In Industrial Networks

FAQ

6. Frequently Asked Questions

Let's tackle some common questions about Modbus, because you're probably thinking them anyway!

Q: Is Modbus really that old? Will it ever completely disappear?

A: Yes, it's a senior citizen in tech years. Will it vanish entirely? Unlikely. Think of it like vinyl records — not the mainstream, but still cherished and used in certain applications. It might fade in prominence, but the installed base is so huge, it'll probably stick around for a good long while.

Q: What are the main drawbacks of using Modbus compared to newer protocols?

A: Security is a big one. Modbus wasn't designed with modern security threats in mind, so it's vulnerable. Bandwidth and data speed are also limitations. Newer protocols offer faster communication and can handle more complex data.

Q: Is Modbus suitable for every industrial application?

A: No. For very high-speed, data-intensive, or security-critical applications, newer protocols are generally a better choice. But for simpler tasks and legacy systems, Modbus remains a solid option.

Q: My boss keeps talking about "Industry 4.0". Does Modbus fit into that future?

A: Yes, but often with a bit of help. Modbus devices can be integrated into Industry 4.0 architectures, often by using gateways or converters to translate Modbus data into formats that are compatible with modern cloud platforms and analytics tools. It's about bridging the old and the new.